Addressing Supply Chain Disruptions Impacting the Audio Visual Industry

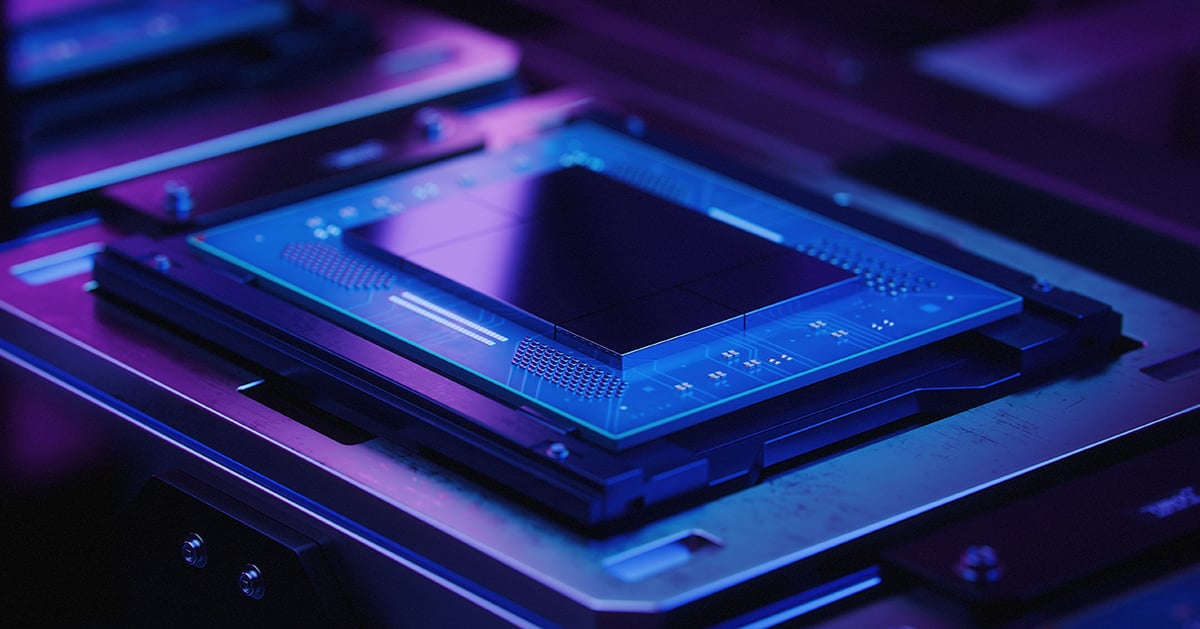

In 2021, experts estimated that the global chip shortage cost the U.S. economy $240 billion. The reality is that manufacturing shortages and supply chain disruption continue to plague production around the world. With the majority of manufacturing taking place in China which has continued to suffer from shutdowns, issues still persist.

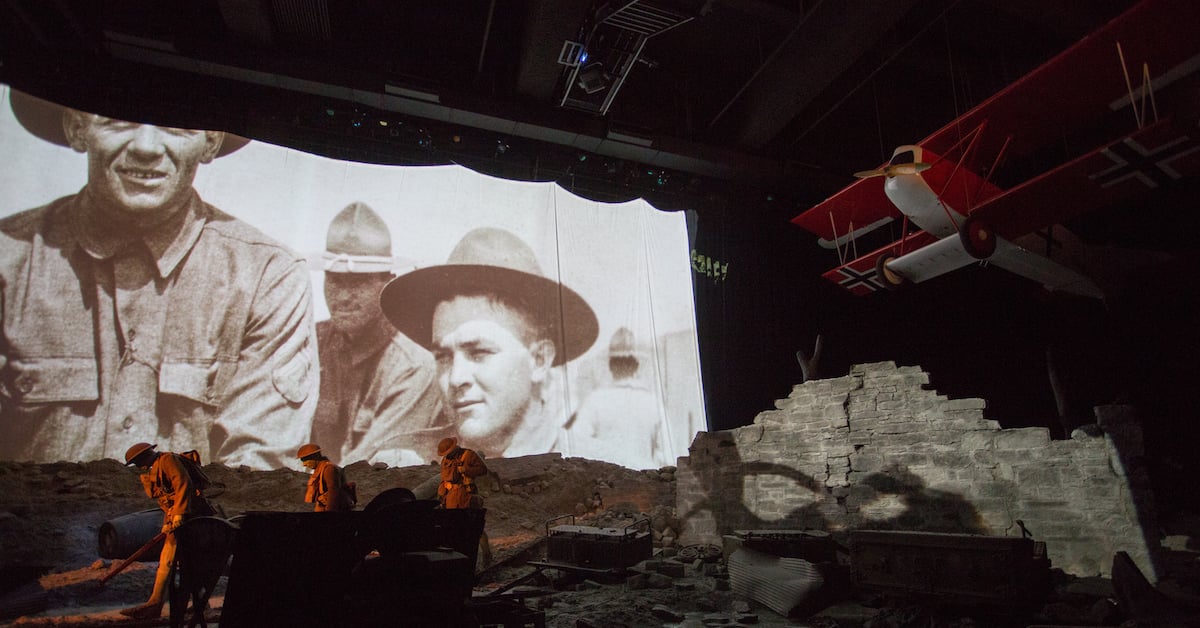

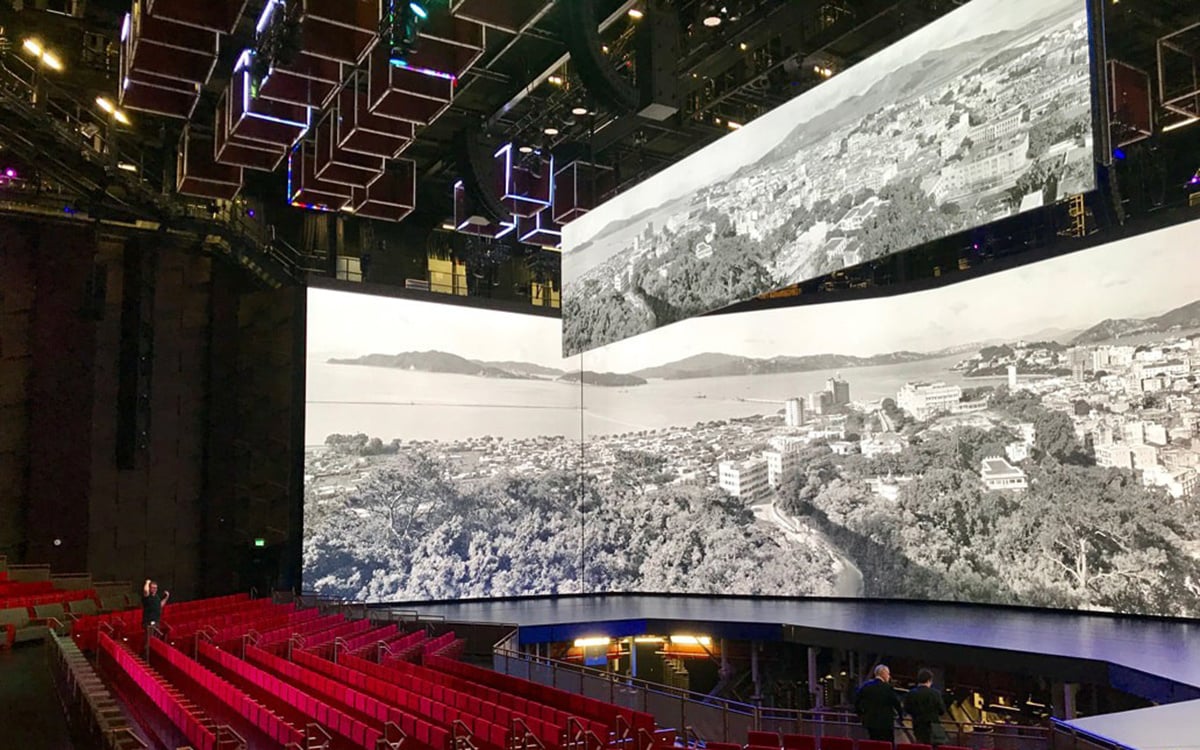

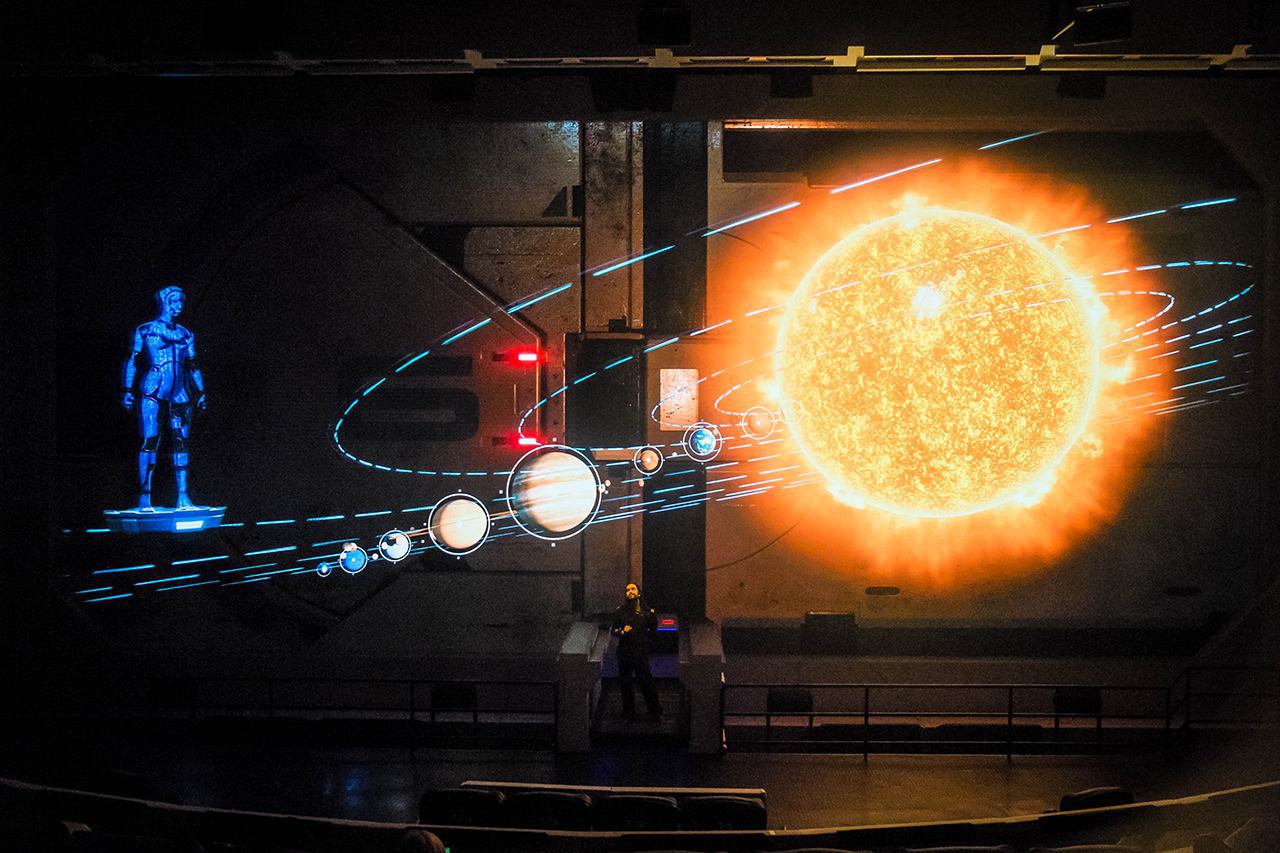

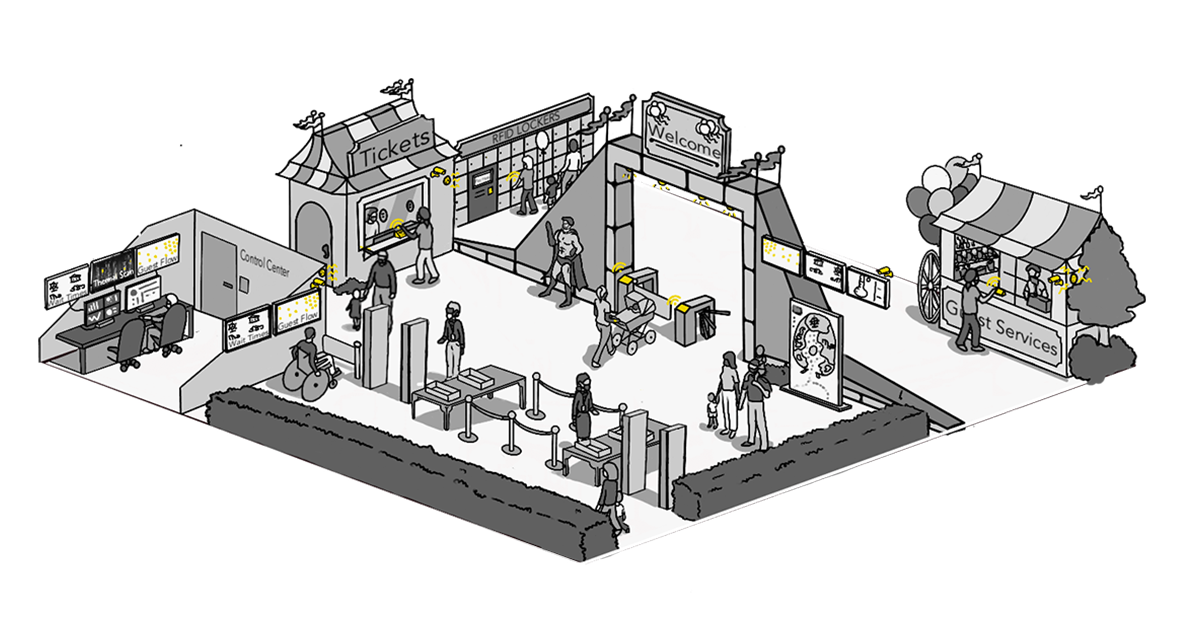

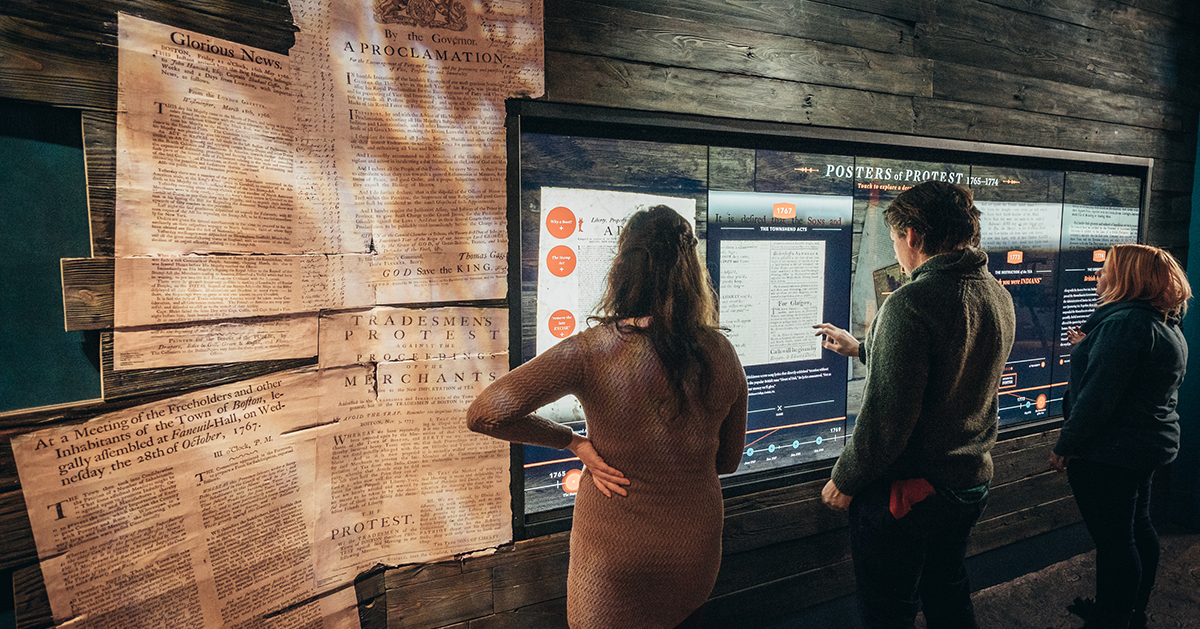

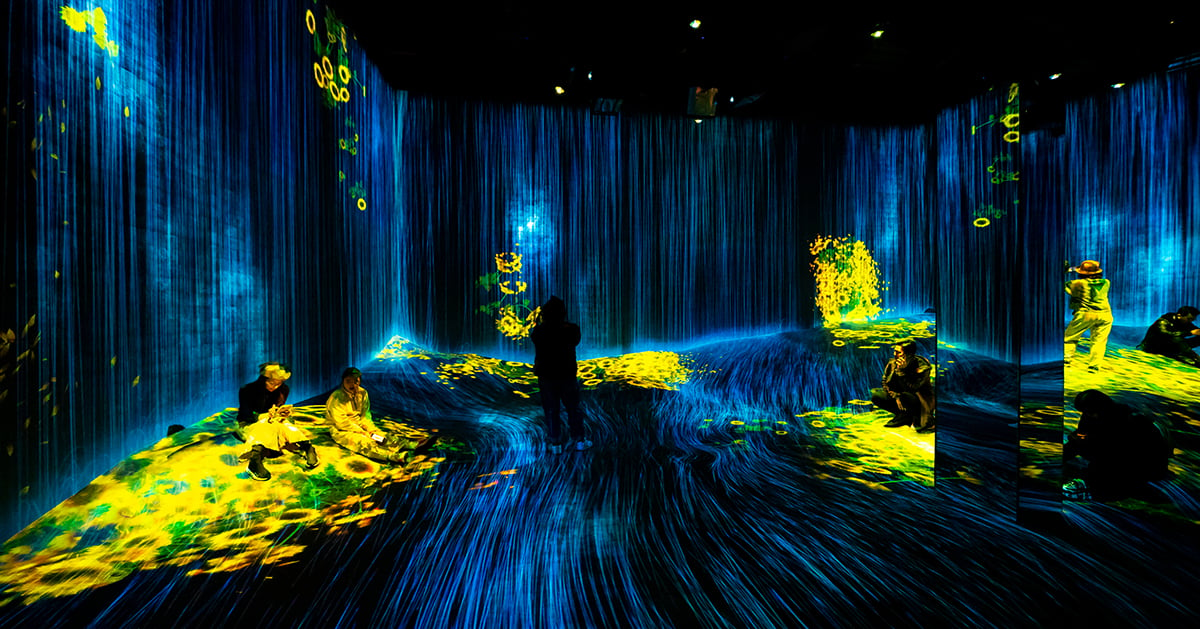

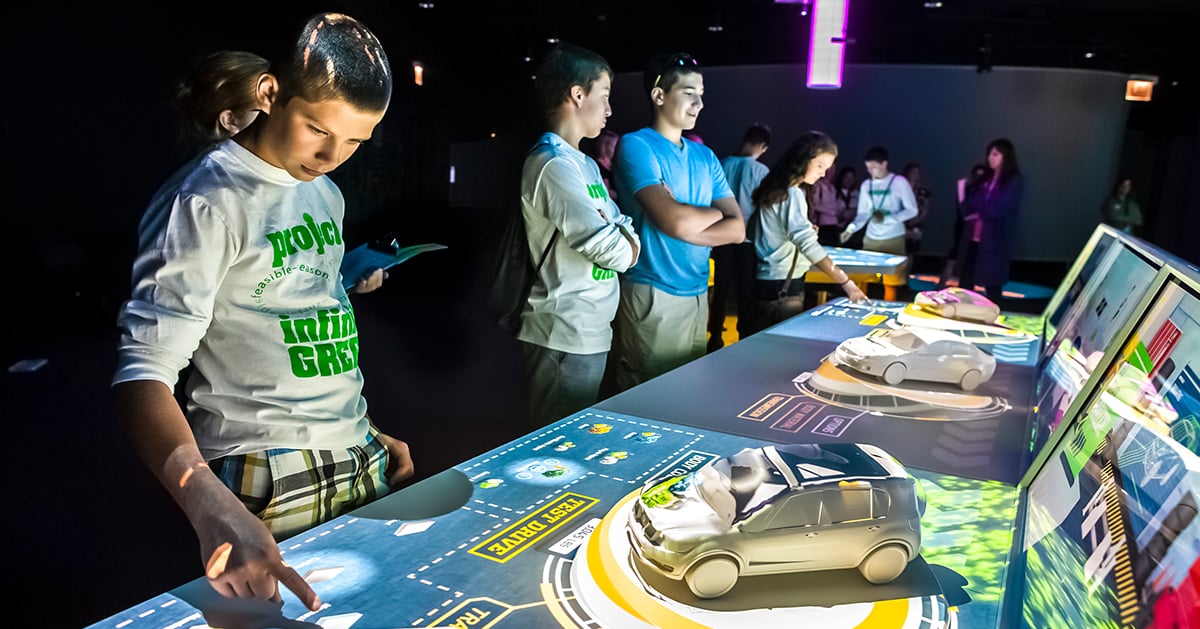

Understanding the current chip shortage includes understanding why so many are needed, how they impact daily life, and what can be done to address manufacturing demands moving forward. First, chips are used in every smart product – computers, phones, refrigerators, grills, cars, and much more. And when it comes to Pro AV, microchips are used to bring imagination to life, from digital signage to immersive experiences, control rooms to exhibits, and everything in-between.

Additionally, when the pandemic hit, demand for microprocessors plummeted leading experts to predict that the trend would continue. The opposite occurred. Demand skyrocketed when people started buying TVs, computers, gaming consoles, appliances, and automobiles in record numbers. Since many of these devices use newer versions of chips due to the fast development cycle of consumer electronics, many semiconductor manufacturers have stopped making the older chips to focus on newer versions.

The Unique Challenges of the Pro AV Supply Chain Crisis

The technology used by the Pro AV industry is designed to have a longer shelf life than consumer electronics due to the massive investment in development and production. The longer refresh cycles of experiential technology products mean they tend to use the older chip versions that are being discontinued leaving the industry with a greater shortage than many others. All of this is forcing Pro AV manufacturers to either buy chips off the gray market or redesign their products around the newer chips.

Technology vendors that were already developing around the newer, more readily available chips have found themselves at an advantage in this environment. Electrosonic technology partner SNA Displays was doing just that, the impact on their products has been minimized. Others are diverting R&D resources to focus on redesigning old products rather than bringing new innovations to market.

In addition to the chip shortage, many manufacturers are also affected by a shortage of raw materials, shipping delays, and rising costs. The current “just-in-time” delivery model many AV providers are working under leaves them vulnerable to even the slightest of disruptions. The ripple effect can result in major delays with some lead times stretching out to over a year. There is at least one manufacturer that is estimating the quarter, not the month, in which a product will ship.

For a good number of Electrosonic’s technology partners availability is product dependent and some, such as QSC, have a wide product portfolio and are often able to adapt designs around available hardware. Designing the right solution now includes an awareness of availability - not just capability.

Identifying Solutions Critical to the Future of AV Companies

The chip shortage is likely to continue into 2023. Identifying and implementing solutions is the first step to finding ways to ensure production continues and partners get the products and services they need when they need them – the potential alternative is to lose business to a competitor.

The state of semiconductor manufacturing has become so grave, that the U.S. Federal Government got involved with the CHIPS and Science Act of 2022 becoming law in August. The law aims to establish semiconductor manufacturing facilities in the U.S. to “build more resilient semiconductor supply chains. The historic funding and incentives in the CHIPS Act will help rebuild our supply chains, manufacturing, and infrastructure here at home, along with crucial invests from the Bipartisan Infrastructure Law and Inflation Reduction Act.”

While this is a potential solution in the future, in the meantime, the AV industry will need to develop solutions that bridge the gap. One of the potential solutions is to begin adopting software designed to meet audio-visual requirements.

Smart Monkeys’ ISAAC platform allows racks of difficult-to-source components to be virtualized – reducing the need for physical products and providing a myriad of other benefits at the same time. Outside of virtualization, engaging closely with an experienced Technology Integrator early and often can help minimize disruption by getting out ahead of the situation.

Getting Ahead of the Game

Disruptions are inevitable but being prepared for them is a choice. Identifying multiple ways to meet product and service needs is a great place to start. Adding in advanced technology able to adapt and evolve provides companies in this space the opportunity to explore new avenues of delivery while supporting innovation.

The time is now to take the opportunity to re-evaluate solution design; invest the time and energy needed to explore alternative methods; and identify a trusted advisor who understands these broader technology trends. Proactively addressing the chip shortage of today can lay the foundation for dealing with supply chain issues in the future.

Ryan Poe

Ryan Poe, Electrosonic’s Director of Technology Solutions, works and writes on the frontiers of advanced technology. He is a trusted adviser on leveraging technology in new ways and works within our Innovation Garage framework to evaluate new technologies and develop resources that support a portfolio of advanced services.

.jpg?width=1500&height=995&name=ELC501_N17_medium%20(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-png.png)

.jpg)

.jpg)

-(1)_1200x629px.jpg)

.jpg)

.jpg)

-RR.jpg)

.png)

.jpg)

.png)

%20(1)-es.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.png)

.jpg)

.png)

.png)

.jpg)

.png)

.jpg)

.jpg)